Honeycombs are composed of two layers of polyhedral cells of hexagonal cross-section. Walls with a homogeneous thickness separate the cells. The formation of honeycombs has fascinated researchers for several years. The question of whether the formation of honeycombs is a result of conscious building efforts by bees or whether it is a physical design principle imposed by nature still needs to be answered.

While most research activities and explanations have been based on the final honeycomb geometry, it is equally important to consider how these structures evolve with time. It was observed that the cells in a natural honeycomb initially have a circular cross-section that transforms into a hexagonal shape with a homogenous wall thickness. This transformation was attributed to surface-tension-driven flow of wax that is solid initially and later softened by heat of the bees’ bodies. However, this explanation is not logical given that the area of the resulting polyhedral structure is approximately 10% larger than that of the initial spherical structure.

Researchers led by Prof. Cosima Stubenrauch at Stuttgart University in Germany conducted a study that pointed to a unique mechanism which can lead to the formation of honeycomb-like structures. “The funny thing is that we were neither interested in honeycomb-like structures nor in osmotic transport when we started this project 4 years ago – the unexpected results forced us to think in this direction”, says Prof. Stubenrauch. In their work, they started with a liquid matrix with closely packed layers of spherical water droplets. A liquid monomer mixture separates the droplets. The mixture was then polymerized, the water was removed, and a solid foam-like material was formed. They showed that if polymerization is initiated at the water-monomer interface, the liquid monomer mixture is transported form the Plateau borders into the filmsin the course of solidification so that the pore shapes become progressively hexagonal. Their work is published in ChemPhysChem.

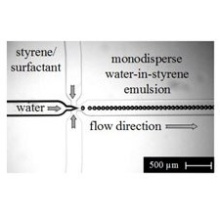

The authors prepared monodisperse water-in-monomer emulsions using microfluidics with a view to fabricating a monodisperse polymer foam in analogy to the formation of porous polymers through emulsion templating. The emulsion was composed of close-packed spherical water droplets, which were surrounded by a liquid mixture of divinylbenzene and styrene. Polymerization of this emulsion with an initiator dissolved in the monomer mixture conserved the geometry of the droplets, and this led to polymer foams with spherical cells. On the other hand, when using an initiator dissolved in water, the formation of a honeycomb structure was observed. The observed transformation of the spherical into polyhedral shaped cells separated by thick walls was attributed to an osmotic transport which could run against the pressure gradient caused by surface tension. For this mechanism to happen, one needs (a) two monomers of different reaction kinetics, (b) to inititate the polymerization of the mixture at the interface, and (c) droplets that are sufficiently large. The idea of osmotic transport being the reason for material redistribution could be implemented in the optimization of the fabrication of lightweight materials. The interface-initiated approach allows for the production of low-density foams with closed-cells. The redistribution of the continuous phase from the plateau border to the films enhances the mechanical properties at constant solid fraction.