The high-pressure view-cells, exhibiting a maximum sample volume of V = 2.3 ml, enable the visual inspection of complex mixtures in a pressure range of 1 bar ≤ p ≤ 400 bar. Transferring the HP view-cell into a water bath allows to control the temperature with an accuracy of ±0.1 K from 10 to 80 °C. Connecting the cell to an in-house built filling apparatus (University of Cologne) equipped with a membrane reservoir, a desired volume of a component being gaseous under atmospheric conditions, as e.g. ethane, propane, CO2, etc., can be added. The HP view-cell was developed at the University of Cologne mainly for phase behavior studies of multi-component systems, as e.g. CO2-microemulsions [1] and CO2, crude oil, additive mixtures for the characterization of CO2-EOR processes [2]. However, experiments are not limited to liquid or gaseous components. Thus, the high-pressure view-cells can also be used for the synthesis of nanoporous polymers [3] following the NF-CID method [4].

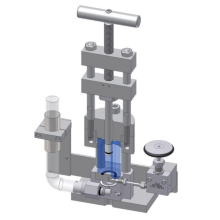

The central piece of the high-pressure view-cells is a pressure-resistant sapphire cylinder (Figure 1 in blue) which allows for the visual inspection of the total sample volume. The pressure inside the cell can be regulated with a tunable piston which also seals the sapphire cylinder from the top. From the bottom of the sample cell, the cylinder can be filled and emptied via a valve (liquid/gaseous components only). The pressure is measured by a pressure transducer (Type 81530, Burster, Germany) also located underneath the observation volume. All connecting parts are sealed with high-precision O-rings made of POM (polyoxymethylene).

| [1] Schwan, M., Kramer, L. G. A., Sottmann, T., and Strey, R. 2010. Phase behaviour of propane- and scCO(2)-microemulsions and their prominent role for the recently proposed foaming procedure POSME (Principle of Supercritical Microemulsion Expansion). PCCP 12, 23, 6247–6252. |

| [2] Rommerskirchen, R., Nijssen, P., Bilgili, H., and Sottmann, T. 2016. Reducing the Miscibility Pressure in Gas Injection Oil Recovery Processes. In Abu Dhabi International Petroleum Exhibition & Conference. Society of Petroleum Engineers. DOI=10.2118/183389-MS. |

| [3] Qawasmi, Y., Atanasova, P., Jahnke, T., Burghard, Z., Müller, A., Grassberger, L., Strey, R., Bill, J., and Sottmann, T. 2018. Synthesis of nanoporous organic/inorganic hybrid materials with adjustable pore size. Colloid and Polymer Science 296, 11, 1805–1816. |

| [4] Strey, R. and Müller, A. Erzeugung nanodisperser Einschlüsse in einer hochviskosen Matrix, WO002012072755A2 |

Maximilian Krappel

Doctoral Researcher

Julian Fischer

Doctoral Researcher