Overview

Microemulsions are thermodynamically stable mixtures of polar and nonpolar components stabilized by surfactants, which are used for various applications. Surfactant flooding is an attractive technique employed in enhanced oil recovery (EOR) to overcome the limitations of conventional recovery methods, which can only extract around 30 % of all reservoir oil. Ultra-low oil/water interfacial tensions (IFT) have been found for microemulsions formulated from so-called extended surfactants, which contain groups of intermediate polarity between their head and tail, enabling particularly high solubilization efficiencies. Prediction of desired properties such as the position of the phase inversion, at which solubilization is most efficient and the IFT runs through a minimum, is achieved for instance via the hydrophilic-lipophilic deviation (HLD). However, to determine the HLD coefficients, knowledge of phase behavior, which is distinctly affected by microemulsion composition and temperature, is required. The role of pressure is typically assumed to be of minor importance; although previous investigations have shown that the pressure effect for short-chain alkanes is stronger and in the opposite direction as for longer, less compressible ones. However, what is yet missing to mimic the recovery of live oils is the systematic study of the influence of the ratio of short-to-long-chain alkanes on microemulsion properties. Performing these studies with very efficient extended surfactants enables further production optimization in EOR.

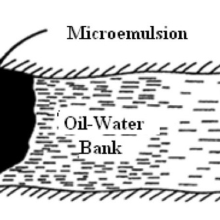

In this project, we investigate the pressure-dependent phase behavior of an application-relevant microemulsion consisting of brine/butyldiglycol, decane, propane or methane, and a surfactant mixture of a commercial alkyl alkoxy sulfate and alkyl sulfonate. New insights into the role of pressure and short-chain alkanes on phase behavior and the curvature of the amphiphilic film are obtained. To enable precise predictions on live oil microemulsions in the scope of the HLD framework [1], the influence of salinity and propane-to-decane (or methane-to-decane) ratio on phase behavior was investigated at constant oil-to-brine ratio, allowing for the determination of HLD temperature and pressure coefficients. Pressure-dependent phase behavior of live oil microemulsions was recorded as function of temperature and surfactant concentration ("fish cut") in a high-pressure view cell at different pressures up to 380 bar [2].

The scope of this project is not only interesting from a fundamental perspective, but also particularly useful for applications. Surfactant formulation design in the lab is typically done at ambient pressure with so-called dead oil. Understanding and predicting the impact of pressure and volatile gases enables a formulation readjustment in order to achieve high oil production under field conditions. Our studies provide novel insights into how pressure affects the surfactant membrane in the presence of short-chain alkanes in synthetic live oil formulations, which in turn influences interfacial tensions and recovery potential. Quantifying the influence of methane and propane in formulations of different salinities, our investigations further allow for a refined prediction of the properties of EOR-relevant microemulsions by applying the HLD concept.

References

- Salager, J.-L., Forgiarini, A. M., Bullón, J.: How to Attain Ultralow Interfacial Tension and Three-Phase Behavior with Surfactant Formulation for Enhanced Oil Recovery: A Review. Part 1. Optimum Formulation for Simple Surfactant–Oil–Water Ternary Systems. J. Surfact. Deterg. 16, 449-472 (2013). https://doi.org/10.1007/s11743-013-1470-4

- Schwan, M., Kramer, L. G. A., Sottmann, T., Strey, R.: Phase behaviour of propane- and scCO2-microemulsions and their prominent role for the recently proposed foaming procedure POSME (Principle of Supercritical Microemulsion Expansion). Phys. Chem. Chem. Phys. 12, 6247-6252 (2010). https://doi.org/10.1039/B909764C

- Bera, A., Mandal, A. J.: Microemulsions: a novel approach to enhanced oil recovery: a review. Petrol. Explor. Prod. Technol. 5, 255-268 (2015). https://doi.org/10.1007/s13202-014-0139-5

Cooperations

- BASF SE, Ludwigshafen am Rhein, Germany

Contact

Maximilian Krappel

Doctoral Researcher

Thomas Sottmann

Prof. Dr.Professor